Tooling applications are diverse, and their production usually entails a complex process and supply-chain, with a wide number of manufacturers. Automotive as well as aerospace industries make extensive use of tools, jigs, and fixtures with specific functional and technical characteristics; therefore, OEMs in these sectors are amongst the first experimenting with large format 3D printing technologies. The following case study introduces the key role of cure tooling and the potentials of Additive Manufacturing for thermoset prepregs molding in a high-end segment such as that of supercars’ production.

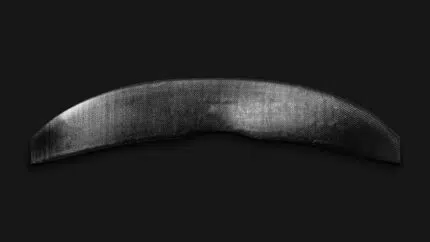

Cure tooling plays an essential role in the manufacturing of automotive parts, enabling carbon fiber lamination of key parts such as car bodies and carter covers that require precision and accuracy. This kind of tools are designed custom on the determined shape of the final car section, ensuring that they meet the specifications required.

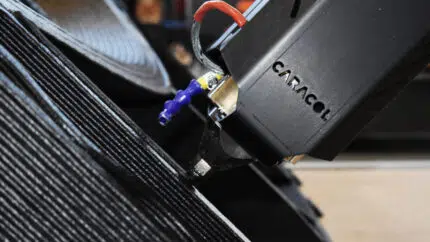

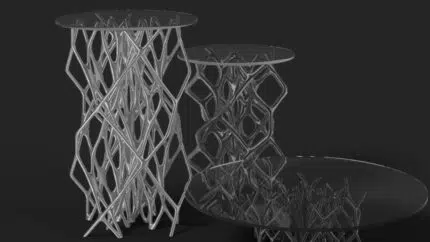

One of the greatest benefits of additive manufacturing, when applied to tooling, is that it is possible to directly produce the mold on which the final part will be shaped and laminated. Compared to traditional manufacturing, this means cutting steps in the process, such as the master model’s production. Moreover, the design flexibility allows to obtain a handling-wise shape for the tool and to reduce the total weight, allowing to simplify logistics in the production site for movement and storage of parts. Most of the time, after printing, the mold is post-processed with CNC to reach surface roughness and dimensional tolerances required for its workable surface. This also allows to equip it with grooves for trimming the final component directly on the mold.

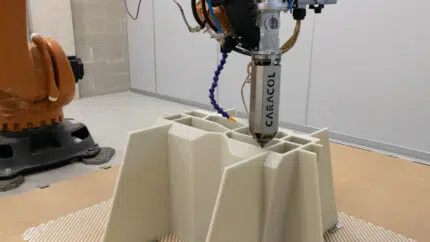

This specific cure tool, used to produce the carbon fiber cover for supercar’s carters, was developed in collaboration with Airtech. The tool for curing thermoset prepregs was manufactured with Airtech Dahltram C250-CF material, a polycarbonate (PC) reinforced with 20% Carbon Fiber (CF). This composite offers great thermal and mechanical properties and is qualified for mid-temperature autoclave processes, as it can go up to 180° C and 6 bars in terms of working temperature and pressure, assuring stability in varied industrial environments and over time. The tool was successfully used to test and laminate the carbon fiber carter finished part.

01. 3D print Autoclave cure tooling for the automotive industry

02. 3D print Autoclave cure tooling for the automotive industry

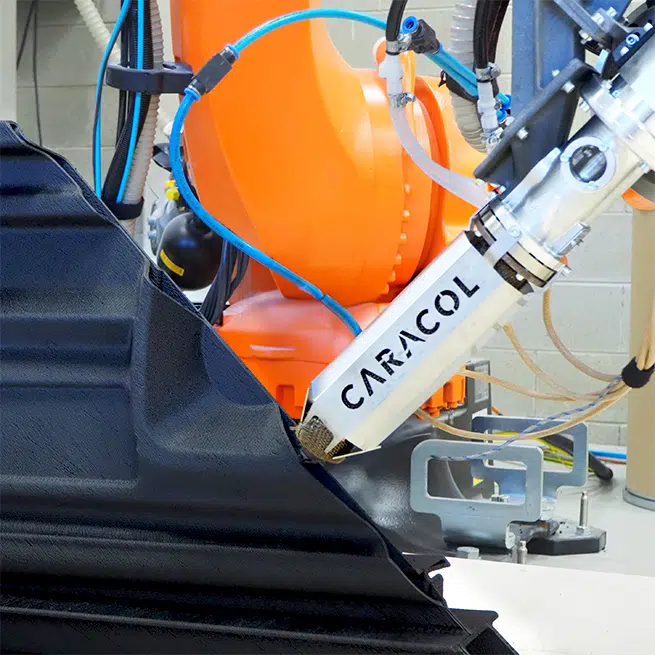

Caracol’s Heron AM platform processes advanced materials like Airtech’s Dahltram C250-CF as well as many other composites in the form of granules. The system can be set up with different configurations, extruder heads, nozzle dimensions – to determine the overall throughput and production specs to render the production process as efficient as possible. For this project, the Heron 300 model equipped with HF (High Flow) extruder was used to manufacture the printed part, then its workable surface was finished with traditional CNC afterwards.

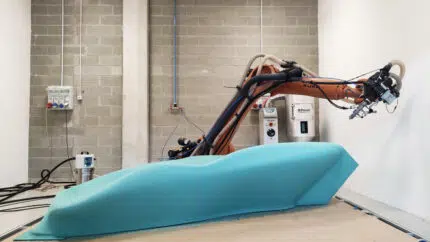

Thanks to the platform’s 6-axes and the several meter wide arm reach, the robotic system can print large format, complex parts in a single working cycle, with no need to assemble nor program several cycles. The overall benefits bear considerable waste reduction, improved lead time and reduced production costs. Furthermore, OEMs could take advantage of the improved performances of the specific finished tool and of the overall process. Finally, by applying Additive Manufacturing technology to hypercars’ manufacturing, Heron AM brings significant process’ optimization and sustainability to both large volumes and niche and luxury productions.

Key Production specs:

TECHNOLOGY: LFAM Heron AM with HF extruder + CNC post-processing

MATERIAL: PC CF

SIZE: 500 mm (l), 500 mm (h), 200 mm (w)

SURFACE ROUGHNESS: 0.8 μm

DIMENSIONAL TOLERANCES: 0.2 mm

WEIGHT: 21 Kg, up to 60% saving

WASTED MATERIAL: up to 70% reduction.

LEAD TIME: from 8 to 2 weeks = saving 80%

COST: starting from 50% savings