A game-changing technology bringing 3D printing to large-scale industrial applications.

Over the past decade, 3D printing technologies have advanced at an unprecedented pace, paving the way for innovative solutions in industries ranging from aerospace and automotive, to mobility, energy, and construction. One of the fastest growing technologies over the past few years, has been that of large-scale 3D printing, which enables the creation of objects on a massive scale.

With Large Format Additive Manufacturing, you can produce functional and intricate designs with a fully digitized process, for the most advanced applications. The encounter of 3D printing extrusion technology with robotics has led to the development of robotic LFAM, an industry-changing solution in large-scale 3D printing, that can help evolve businesses in terms of flexibility, efficiency, and sustainability.

WHAT IS ROBOTIC LFAM?

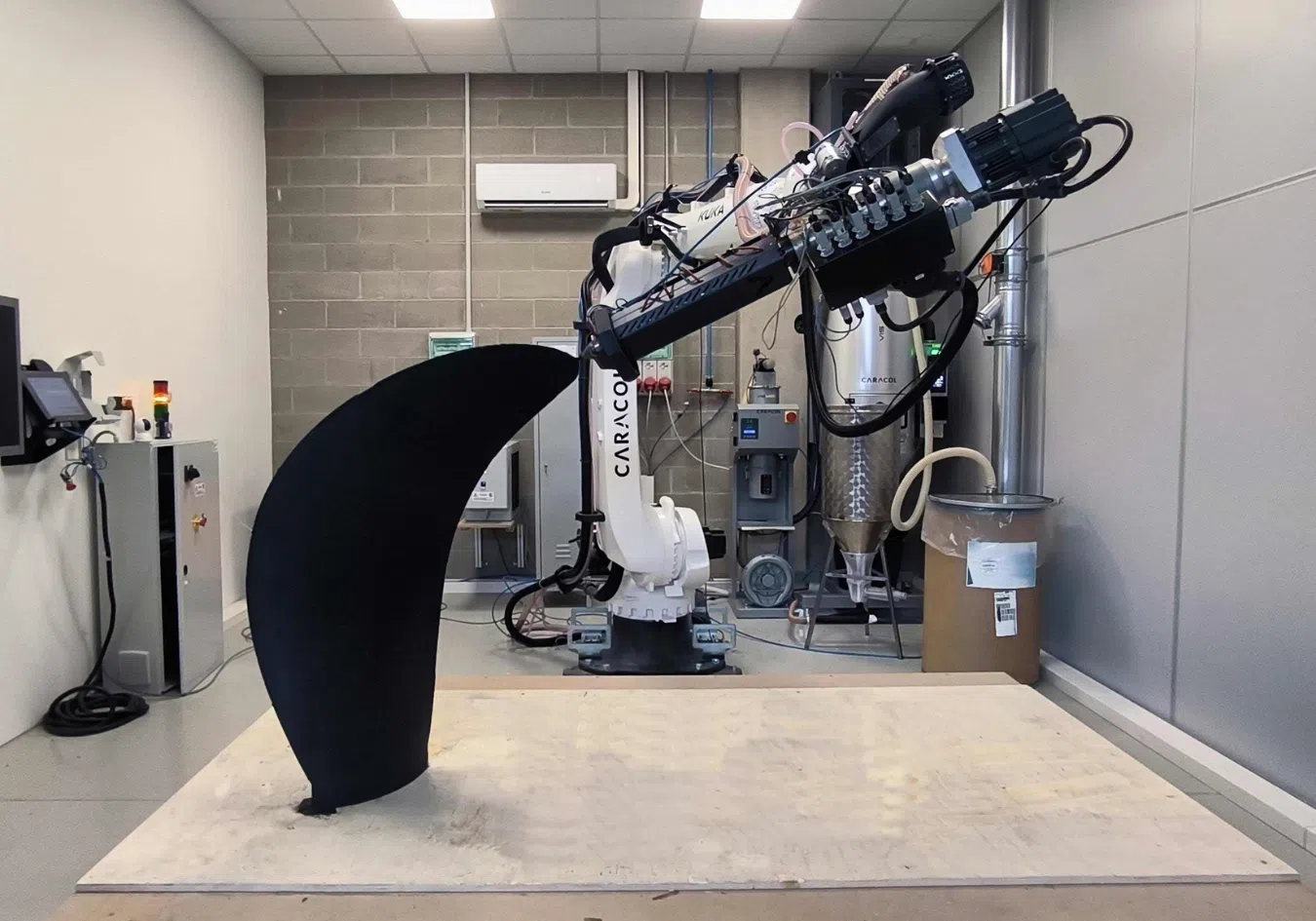

Robotic Large Format Additive Manufacturing consists of integrating 3D printing processes with a robotic movement support to print parts without limits in scale, and without the constrains of traditional 3-axis cartesian frames. With this cutting-edge technology, it’s possible to create three-dimensional objects on a significantly larger scale than traditional 3D printing techniques. Parts can be several meters in size, with complex and even intricate geometries. Starting from 1 cubic meter, this technology can penetrate highly demanding industries where parts’ dimension and manufacturing lead times are key factors to achieve a sustainable business case, while fulfilling requirements in terms of part performance. LFAM can enable the production of parts that are as precise, durable, and efficient as traditional manufacturing methods, while delivering process benefits in terms of scale, faster production times, design flexibility and sustainability of the whole supply chains.

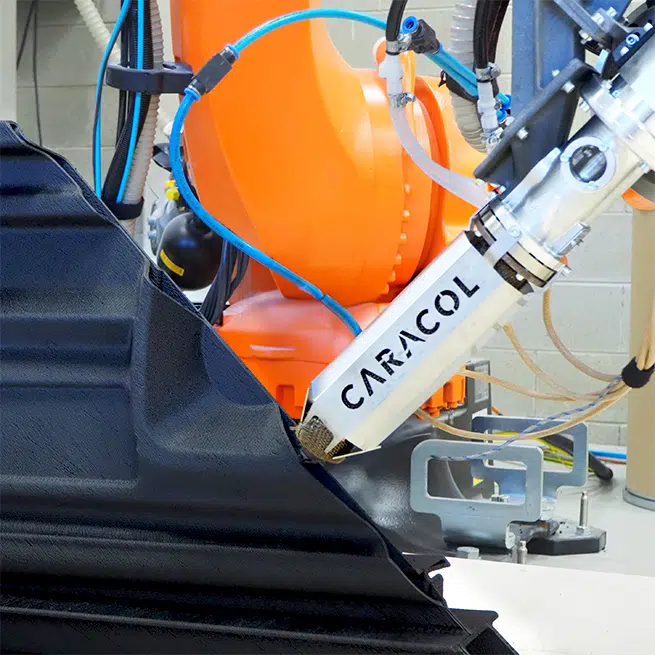

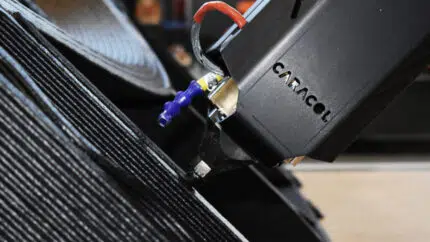

The LFAM systems developed in-house by Caracol use FGF process to fully leverage the 3D printing benefits on large-scale, and are conceived to guarantee flexibility, efficiency, and sustainability.

WHAT DOES FGF 3D PRINTING MEAN?

Fused Granulate Fabrication is an extrusion-based technology where pellet-form thermoplastic materials are 3D printed. Coming from different sources, plastic materials can be natural, filled with fibres (composites), recycled – with a strong focus on using end-of-life materials, optimized for this technology (circular economy). For the industrial 3D printers based on FGF technique, such as Caracol’s Heron AM platform, the extrusion system is key. Therefore, Caracol’s mechanical engineers develop internally a range of end-effectors with different output capabilities and performances, to meet specific application needs in several industries that use different materials. At the same time, a specialized team oversees testing and qualifying materials, to guarantee quality and efficiency of the process with Caracol’s LFAM robotic platforms; and the company collaborates with trustful materials suppliers to strategically push LFAM further into the industrial world.

THE ADVANTAGES OF FGF 3D PRINTING

Supply chains and material feedstock: FGF process allows to work with thermoplastic materials, with a cost that is much cheaper compared to other forms of 3D printing materials (e.g., filaments, powders), and take advantage of already well-distributed supply chains and a consolidated industry, allowing to perfect these compounds by designing custom material recipes for best-in-class 3D printing processes.

Composites for advanced applications: polymer pellets can be easily reinforced with fibres in a high percentage, achieving high-end mechanical properties, and obtaining very technical materials overall.

THE BENEFITS OF COMBINING ADDITIVE MANUFACTURING WITH ROBOTICS FOR LARGE-SCALE APPLICATIONS

A matter of size: as industrial robots are available in different sizes and with different arm extensions, they are key to produce large-scale applications, even with complicated geometries. Starting from the variety of robot sizes, it’s possible to configure different machine layouts starting from the same set-up architecture. Heron AM platform can be configured with different robotic arms, according to the specific customer needs.

All about flexibility: the anthropomorphic movements of the robot provide extreme flexibility and freedom in designing and realizing the most daring shapes and geometries, unlocking the full potentials of 3D print technologies. The robot set-up allows the user to program a 6-axis printing machine; but Heron AM platforms can go even further. Through the integration of external axes such as a positioner or an additional 7th axis, it’s possible to extend the scale and the geometrical complexity of the printable parts. Heron AM platforms, indeed, leverage the multi-axes 3D printing processes to enable more complex and optimized shapes, compared to traditional technologies.

Simplified access to robotics programming: Since robotics entails complex cinematics, Caracol’s technological developments focus on software too. With users’ needs in mind, Caracol’s software solutions guarantee an easy and assisted way – fully integrated with the 3D printing process – to program the robotic motions in planar, multiplanar and not conformal modes.

Want to know more about robotic LFAM? Talk to Caracol’s experts to try out LFAM technology to print your large-scale components, get in touch with us directly or learn more about Heron AM right now.