Pushing Caracol Large Format Additive Manufacturing robotic platform Heron AM into a new era for industrial production

BARLASSINA (MB), ITALY – Caracol, leading company in large format robotic 3D printing, launches several innovations on its technological platform – from hardware to software – at Formnext 2023 (Frankfurt, Germany), and hosts a panel discussion on the LFAM market with key companies representing the segments’ value chain on November 8th.

On November 7-10, 2023, Formnext 2023 – the international meeting point for industrial manufacturing professionals and 3D printing experts – takes place in Frankfurt. Also this year, Caracol renews its participation showcasing its latest launches and novelties at booth C59, Hall 12.1.

For this year’s edition, the company wants to put a spotlight on the whole large format 3D printing value chain – from materials, to hardware, software, and applications – with the aim of fostering awareness and demonstrating what benefits these innovative advanced technologies can deliver to manufacturing supply chains.

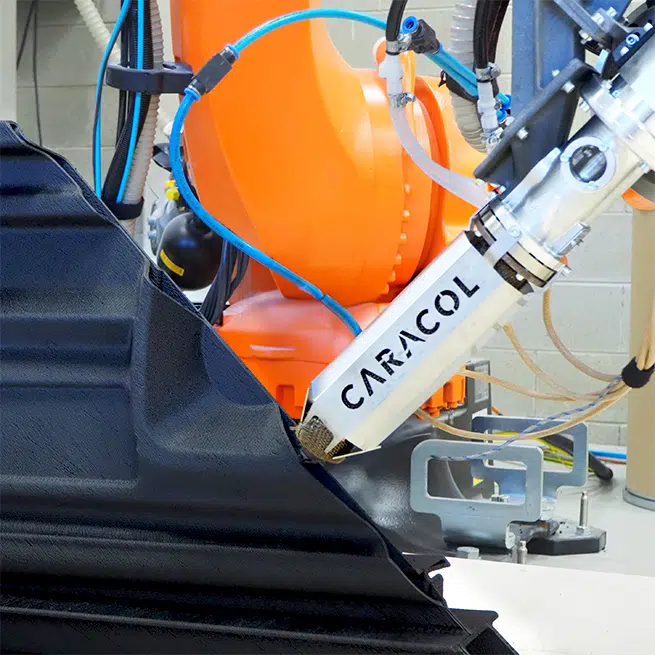

Caracol’s patented robotic platform Heron AM is center stage at the company’s booth where 3 product launches will be presented, including: hardware, software and automation.

Starting with the company’s latest hardware launch: the High Versatility (HV) extruder. This product completes Caracol’s portfolio of 3D printing heads, providing a tool that is designed to answer customers’ need for an extremely flexible system. It is the ideal solution to deliver precision, performance on advanced materials, as well as speed. The new end-effector was designed to perfect the manufacturing of a broad range of applications with a single tool: from finished parts, such as marine super structures, architectural panels or furniture parts, as well as small to mid-sized tools, jigs, and fixtures. Caracol’s range of extruders provides the ideal technological solution to cover all manufacturing needs and applications clients might have printing large scale parts. Each of them processes a wide variety of thermoplastic pellets, from composite fiber-reinforced to recycled or bio-based materials. The High Versatility extruder joins Caracol’s extruder range, together with the lightweight and compact High Accuracy (HA) model and the high-throughput and robust High Flow (HF).

To provide clients with full control, flexibility, quality control, and repeatability of the manufacturing process Caracol is launching its expanded Eidos Manufacturing Software Suite, that covers a wide range of features. Beyond its Parameters & Path Planning software and its HMI – Human Machine Interface to activate and directly control the platform, the company is launching Eidos – IoT. This new module introduces remote smart monitoring for customers to manage their full fleet of machines in a simpler and quicker way. It includes features such as condition monitoring, process monitoring, digital twin, predictive maintenance, cloud data logging and analysis of numerous variables concerning the system, the printed part, and the working environment. Its integration with Caracol’s hardware Heron AM truly guarantees a turnkey system that is efficient and controls the full production cycle, to deliver production continuity and reliability.

The Heron AM platform is designed as a modular system that can be configured and customized to satisfy client’s needs; this is why Caracol is launching a new control cabinet that can manage multiple end-effectors on a single system. Developed to manage the HV and HF extruders, this innovation provides a unique and centralized control unit and a plug-and-play logic, to enhance all key elements’ integration. With this solution, clients can enhance their manufacturing flexibility and maximize their investment on a single platform, adapting it to changing needs and applications.

Starting on November 7th, visitors will be able to see the company’s robotic system Heron AM printing live with advanced materials provided by Caracol’s newly announced materials partner Airtech – Advanced Materials Group. Together, they’ll be showcasing the potential of Airtech materials and Caracol technologies for the architecture and construction sector. Visitors will also be able to explore all of the new launches, and see firsthand what Heron AM can do with the extensive showcase of parts, manufactured for leading brands from different industrial sectors. Starting with the train nose manufactured for Alstom, to the automotive grille printed for Gas Monkey Garage and Titans of CNC with Sabic materials, to the helicopter nose lamination tool produced for Loson with Airtech materials, as well as parts from the marine, design, and furniture sectors.

As evolving Additive Manufacturing means raising the bar of an inherently innovative industry, Caracol has also decided to go beyond its own work as an AM technology provider, to express its desire to shape the future of Additive Manufacturing through collaboration and sharing of its experience with other companies in the market. To do this, Caracol is bringing together a panel of leading companies in large format AM, to represent several points of view on the markets’ evolution over the past few years and its upcoming future: from materials to software, hardware, and service. The panel will take place on Wednesday November 8th, at 4:00 pm CET (16:00) at Caracol’s stand C59, hall 12.1. It will include the CEO of the French-Swedish robotics software company Adaxis; the CEO of the UK-based AM software-as-a-service company Ai Build; the Director of Additive Manufacturing for Airtech, the largest manufacturer of vacuum bagging and composite tooling materials also for 3D printing; the Additive Manufacturing Lead for CMS S.p.A., key manufacturer of industrial machinery for the processing of a wide variety of materials; the CEO of the US manufacturer of FDM and FGF printers Filament Innovation; and the CEO of Solidtech, Portuguese 3D service provider, specialized in manufacturing small series plastic parts. The speakers, moderated by Caracol’s CEO Francesco De Stefano, will provide their perspective on the potential of LFAM for industrial applications, and discuss the positive impact that partnerships between companies can provide to further expand this growing market segment. After the panel, Caracol will open its bar area, with music, food, and drinks!

Who We Are

Build beyond possible

Born from the idea of pushing the limits of 3D printing beyond what was possible, Caracol offers Large Format Additive Manufacturing solutions for advanced industries.

Meet Caracol