A partnership to deliver LFAM to Japan and South Korea.

[15 January • 2024] – Caracol and 株式会社3D Printing Corporation are excited to announce their partnership, to bring advanced robotic large-format additive manufacturing to Japan and South Korea.

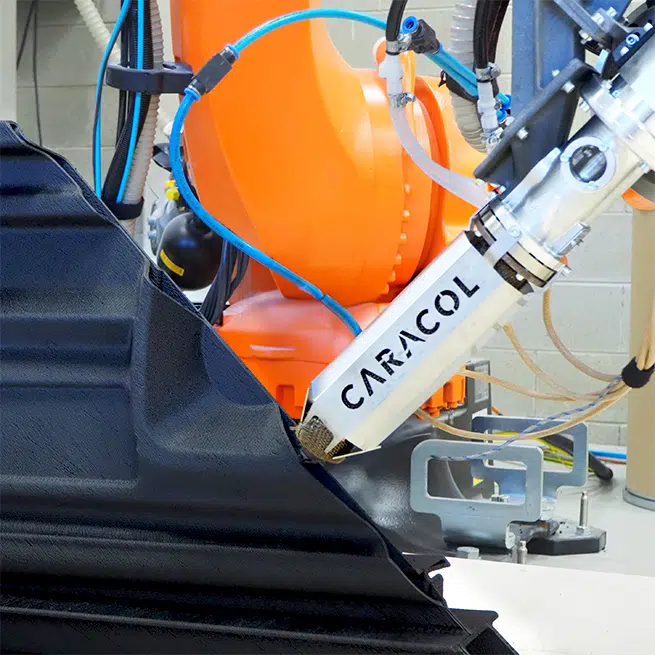

3D Printing Corporation will be installing a Heron AM platform within their facility to manufacture large-scale parts locally, becoming part of Caracol’s Manufacturing Partners network, as well as supporting the distribution of these machines in Japan. The company decided to introduce LFAM after careful analysis of the innovations currently present on the market, “Pellets as a feedstock is a fundamentally better idea to lower costs and increase productivity. We decided to partner with Caracol because of their deep know-how around manufacturing large and complex objects in novel materials,” says Alexander De Vore, CEO of 3D Printing Corporation. The company’s aim for him is “Transitioning manufacturing to a digital process. By doing this we believe we are making everyone who makes things more productive and align the world around making and using things more locally. Our efforts are currently focused on building solutions around tooling, recycling, and operational sustainment.”

Caracol values partnering with a strong partner who can support the growth of LFAM within the Japanese and South Korean industrial landscapes with knowledge on local cultures and needs. “Caracol is very happy to partner with a leading technology provider and service bureau, bringing Heron AM to Japan and South Korea.”, says Francesco De Stefano CEO of Caracol. “Japan has the largest robotic market in the world and has historically driven the adoption of many new disruptive technologies. Thanks to the experience and cultural understanding 3DPC has of this territory, as well as their incredible solution-driven production capabilities, we are confident we’ll be able to guide across industries many new users to manufacture advanced parts with LFAM.”

Japan and South Korea have been slowly but steadily growing their interest towards additive technologies – especially considering the strong advanced industrial and technological background the countries possess. According to Alexander De Vore “Japanese AM needs to be viewed in the context of the broader shift towards digitalization happening in Japan. It’s paradoxical but Japanese AM lags behind its Chinese, American and European counterparts because it has a highly developed manufacturing market. That same developed market sets a high minimum hurdle to clear and combined with the confucianist tendency to view any perturbation with skepticism, the natural new technology discovery process tends to happen very slowly, if at all.”

Today the shift is happening also thanks to companies like 3D Printing Corporation who are delivering solutions to the market, thanks to the possibilities of additive manufacturing. “Our growth in the market has largely been based around providing solutions to problems that were largely unsolved within this traditional manufacturing market. LFAM, Pellets, and robotics just builds on this by giving us more radical capabilities,” states Alexander De Vore. Through this partnership Caracol and 3D Printing Corporation will seamlessly be able to deliver to Japanese companies the know-how and experience developed over years of research on LFAM, helping them leverage quickly the benefits these solutions can provide for their manufacturing needs and goals.

Who We Are

Build beyond possible

Born from the idea of pushing the limits of 3D printing beyond what was possible, Caracol offers Large Format Additive Manufacturing solutions for advanced industries.

Meet Caracol